Posted 2006-09-01. Permalink. Send Comment. Prev.

As described previously, the piece I have now is a 27mm OD, 3mm think brass disk with a ⅛ inch hole drilled in the center. After parting, the parted face is not as nice as the turned face, as well as having paper thin circle of brass protruding around the center hole where the parting tool cut through. I will probably clean this up using a hand file, but if I were game, I would make a Thin Piece Collet for it and use that.

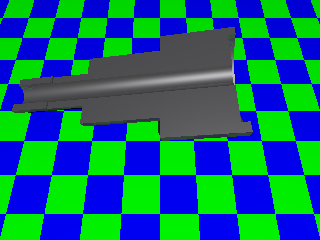

A thin piece collet is a very simple workholder for holding thin, circular pieces, such as washers. It is made from round bar slightly larger in diameter than the desired work piece, turned down in two steps, drilled through the middle, and then split almost in half with a hacksaw or band saw. For example, to hold my 27mm OD, 3mm think brass disk, I would make it something like 60mm long, in three 20mm steps, 10mm OD, 20mm OD, 30mm OD, and drill through the middle with a 6mm drill, then turn a 27mm, 2mm deep insert in the large end, and hacksaw from the large end to 5mm short of the small end. I would draw up the piece in QCad, but it has been a while and I have forgotten how to use it, so I will do some povray 3D renders instead.

Rotating Thin Piece Collet |

Cross Section of Thin Piece Collet |

The work piece is inseted into the end of the collet, and then the collet is placed with the back of the first step against the chuck jaws, and the jaws grip the middle step, clamping on the work piece.

The collet can be reused by inserting a 6mm place holder into the drilled hole, clamping it without any workpiece, optionally facing it off and creating a new insert in the end. This is described in Lathework: A Complete Course by Harold Hall which I am reading at the moment.

Posted 2006-09-01. Permalink. Send Comment. Prev.